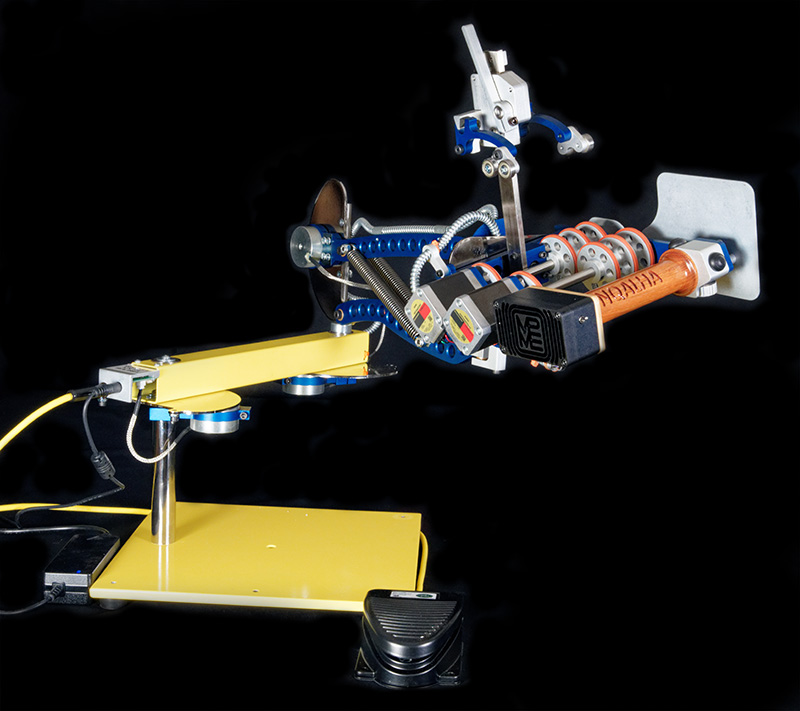

Positioning and spinning machine for glasswork

Extremely wide positioning range, including true vertical, up and down

Electromagnets lock in place and release when lever is pressed

Variable speed thumbwheel control

Footpedal controls pause and reverse in rotation mode

Footpedal controls start and stop in positioning mode

Rotation or positioning mode is selected by a toggle switch

Hand made, in the USA, by the inventor, using CNC and manual tools

Made of anodized, aircraft grade aluminum (6061-T6) and nickel-chrome plated steel

High quality, Oriental Motor (Japan) stepper motors (used in industrial automation)

Powder coated base and horizontal arm

Hardwood handle

High temperature (200C) PTFE wiring in steel flex conduits

Other wires protected by metal mesh

Critical screws secured with Loctite

Bearings secured with high temperature Loctite

I make NQALHA parts in batches called production runs. Once the parts are made and anodized, plated or powder coated, assembly can begin. Since storage space in my shop is limited, I do not assemble units for stock. I assemble units after a deposit or payment is received. If there are no orders waiting, a unit is assembled immediately, otherwise units are assembled in the order that deposits or payments are received

Units take about 1-2 weeks to assemble and test, depending on the number of orders waiting

I do not take deposits or payments for units when a production run is sold out. I add names to the waiting list. There is no cost or obligation to be added to the list, it simply serves as a rough guide for how many sets of parts to make in the next production run

Shipping is included for shipments to the US lower 48 states

Sales tax is added for shipments to California

Price is unchanged from Version 1

Max workpiece diameter 65mm. Min workpiece diameter 7mm

Maximum speed of the drive rollers is 281 RPM, Minimum speed is 0.009 RPM

The rotational speed of the workpiece depends on the mathematical relation between the drive roller diameter and the workpiece diameter

Weight capacity

I hung a 5 lb dumbell on a steel rod 7" from the face, and the NQALHA held it

During testing, I saw a large solid object being made. Precise measurements are not available, so I rely on eyeballic estimates. The object appeared to be 6" long and 6" in diameter, with a big moil, on a steel punty. The NQALHA could rotate it if it was on center and no paddle pressure was applied. Looks like we found the limit

The NQALHA is intended to be a flexible, configurable tool for artists. The standard model may be good for many, but options are available

The standard NQALHA base is a 12 x 12 inch piece of 3/8 steel plate on rubber feet. This option provides the maximum portability and adaptability. You can put it on any bench, in any position

As glass artists integrate the NQALHA into their work routine, they may find that they want different mounting options

One option is permanent attachment to the workstation with screws. I do this on my bench, and other users have done similar things on their workstations

Other options are being explored as more glassworkers use the machine and offer ideas for improvement

The NQALHA drive rollers are very precisely made, but they're not perfect. Same with the O-rings and the glass itself. As a result of this, the glass will drift sideways when rotating

Drift is unpredictable and depends on many factors. The most important factors are time and pressure. If you are doing a fast operation, like flaring a tube, drift will not be a problem. If you are expecting the workpiece to be rotated for a long time, drift must be understood and managed. If you apply pressure along the axis, the workpiece will move

Some glassworkers manage the drift using techniques like sharpie marks, direction reversal and manual repositioning

For positive control of drift, lock collars, a maria or the new integrated blowhose swivel are required. Lock collars are applied to the rod or tube and tightened with a screw. The lock collars fit in the space between the two forward drive rollers and stop drift

The new integrated blowhose swivel is still under development, but early tests look promising

Two options for lock collars exist

Standard industrial shaft collars can be used. They are available from stock and are inexpensive. Unfortunately, every size uses a different sized screw, so a collection of hex drivers will be needed when working with multiple sizes. Also, aluminum collars gall against the aluminum rollers and steel collars are heavy

MPM&E sells custom delrin lock collars. All sizes use the same screw. Since they are custom made, they are more expensive than off the shelf industrial products. Also, since they are plastic, they can melt or ignite if they get too hot. Many glassworking procedures can be successfully completed without overheating the delrin lock collars

The NQALHA fits securely in a slightly modified Pelican case. Other less expensive road case options are being investigated

Before using the NQALHA, it's necessary to know how to safely deal with hot glass and glassworking torches. Make sure you have learned basic handwork skills before attempting to use the NQALHA, and that you are experienced in safely working with hot glass and hot flames

I've encountered a few misconceptions when showing the NQALHA

A few experts fear it will take the skill out of glasswork

Some novices hope it will allow them to make work beyond their skill level

Some call it a robot

It's not a robot. It's not a magical shortcut that will allow you to bypass years of work. It's a tool .. an assistant. Like a belt sander for woodworking, it does the boring or tedious work, allowing the artist to concentrate on the art

It can relieve some of the pain glassworkers feel when spinning a heavy piece for a long time. It can reduce the chance of Repetitive Strain Injury. It can help injured glassworkers continue their art. It can provide an adjustable workholding platform. It can provide a uniform spinning surface that the glassworker can manipulate with two hands. It can give a moment of relief in an artform that's sometimes brutally hot and demanding

It won't magically turn a novice into a master. In fact, some master handworkers struggle with it the first time they use it and some handwork techniques don't translate well

Like a guitar player learning to play the saxophone, it's a new instrument that requires many hours to master. The master "virtuoso" technique has not been invented, but the NQALHA opens up an exciting new world of possibilities to explore

I'm excited to see the new techniques that creative people invent when using this new tool

Remember, the electric guitar was invented for Hawaiian music. Years later, creative musicians used it to invent rock and roll. Years after that, others invented heavy metal

The NQALHA has a "lifetime" warranty (my lifetime, I'm 70). As long as I'm able, I'll do whatever I reasonably can to support users of the NQALHA. Any defective part will be replaced for free. If you damage or destroy anything, parts will be available at a reasonable cost. As the design evolves, upgrades will be available, either free or at a low cost, depending on the details

Since the NQALHA is large and heavy, and shipping is expensive and potentially damaging, maintenance and repair is better done on-site. The NQALHA is a modular design. All parts can be replaced at the module level. The buyer needs to have a set of basic hand tools (hex drivers, wrenches, wire cutters..etc), and the ability to work with screws, cable ties and connectors

Buying an NQALHA is a bit different from buying most commercial products. It's more like joining a club, where the inventor loves working with the artist to perfect the invention. I love glass. I love art. I look forward to working closely with artists as they make beautiful and amazing creations with my invention

I intentionally priced it low in order to make it affordable to glassworkers

A commercial shop, making a machine of this quality and complexity in very low volume would sell it for $30,000, $40,000, or more .. after a quarter million in R&D. I'm not joking or exaggerating. This is the economic reality of the places I worked at for most of my professional career

The project is a labor of love. I'm an artist, making tools for artists. I would love to sell it for less, but I have bills to pay

Version 2.9

Added twist magnet overtravel stop

Minor dimensional changes and process improvements

Functionally equivalent to V2.7 and 2.8

Version 2.8

Minor dimensional changes and process improvements

Functionally equivalent to V2.7

Version 2.7

Changed magnet mounts to leaf spring

Removed unused functions and cleaned up firmware

Version 2.6

Added Right Hand version

Changed to cold rolled steel for better surface finish

Improved travel lock

Changed drive wheel manufacturing process for better accuracy

Version 2.5

Added precision ground main shafts

New software modes

USB firmware update

Version 2.4

Added stronger clamp bar

Version 2.3

New heatsink design

Version 2.2

Added hinged magnet rings on twist axis

Version 2.1

Improved twist axis axle

Added hinged magnet rings on vertical axis

Version 2.0

Stronger, one piece handle

Ball bearings on the horizontal arm to increase smoothness of motion

Additional control mode that locks twist axis while allowing vertical motion

New software with many improved functions

Hard stops on horizontal motion to prevent over-rotation

Metal mesh covering on magnet wires to protect against heat

Nickel-chrome plating

Version 1.0

Initial release