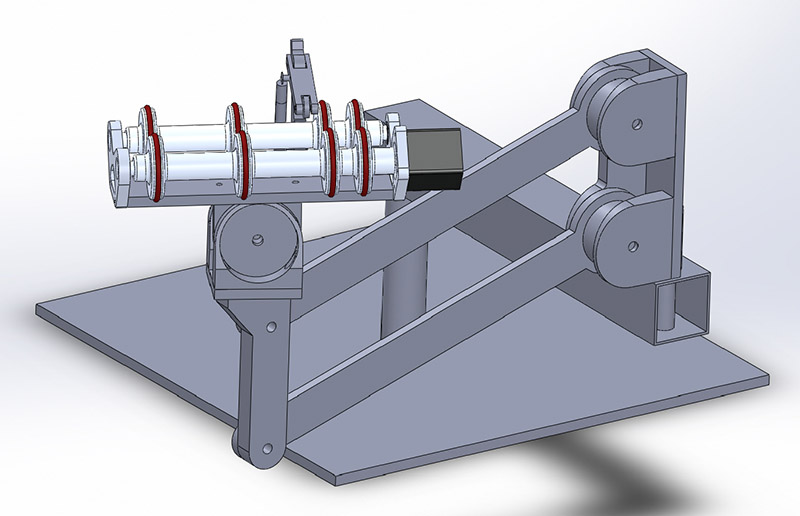

The First CAD model

The project was started before the CNC Bridgeport arrived. The CNC router can cut aluminum, really slowly, with sturdy fixturing, mist coolant and light cuts

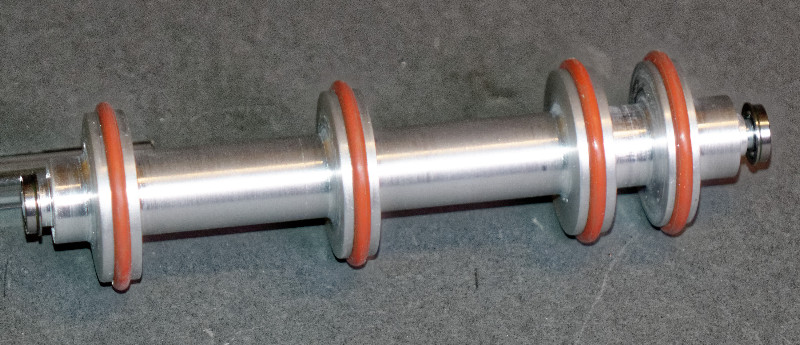

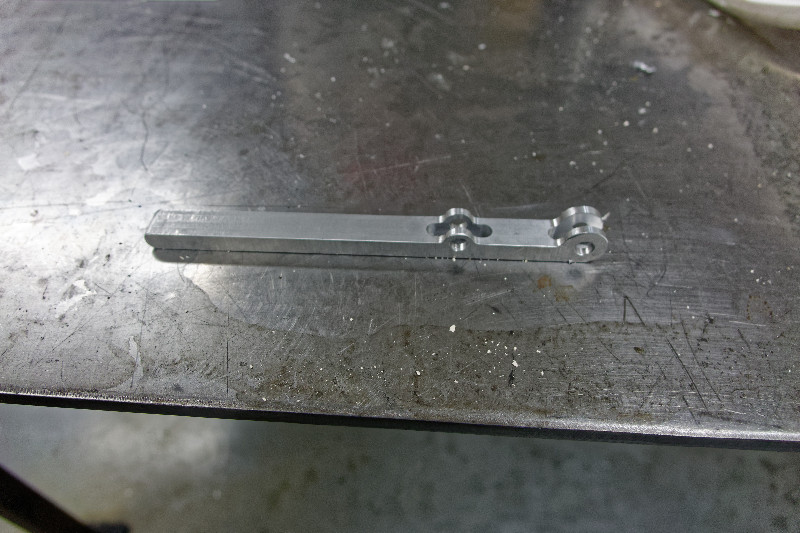

First spindle, made by hand on the a crappy Chinese metal lathe. Took all day. This is a hard part to make. I need to find an alternative

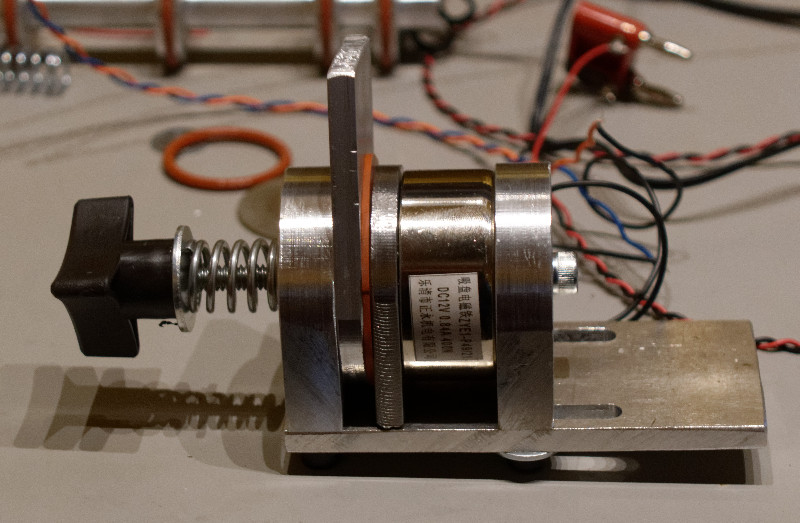

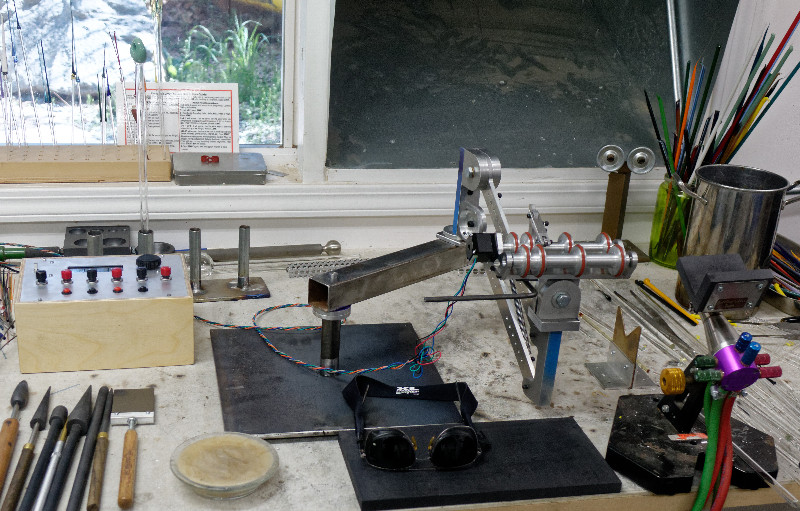

Test fixture for developing the spring-applied, electrically released, braking joint. When the project was started, this seemed like a good idea

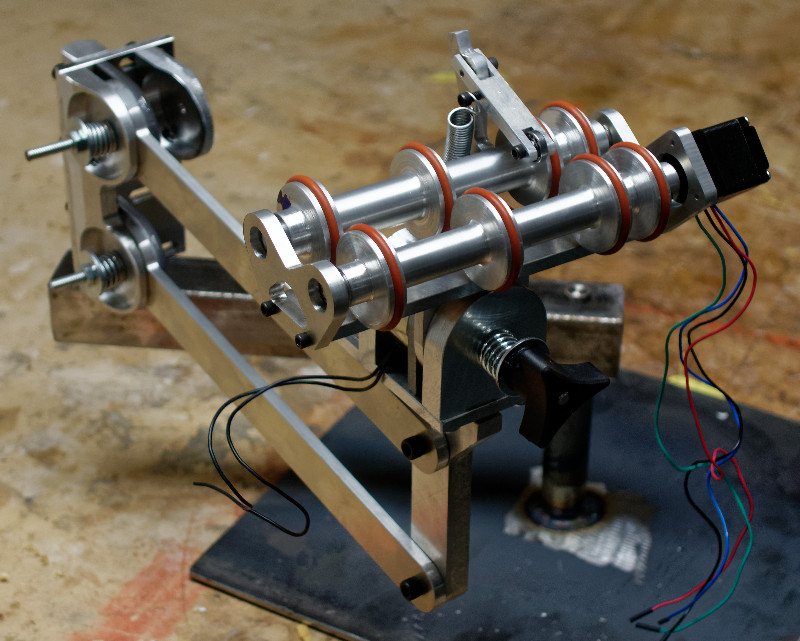

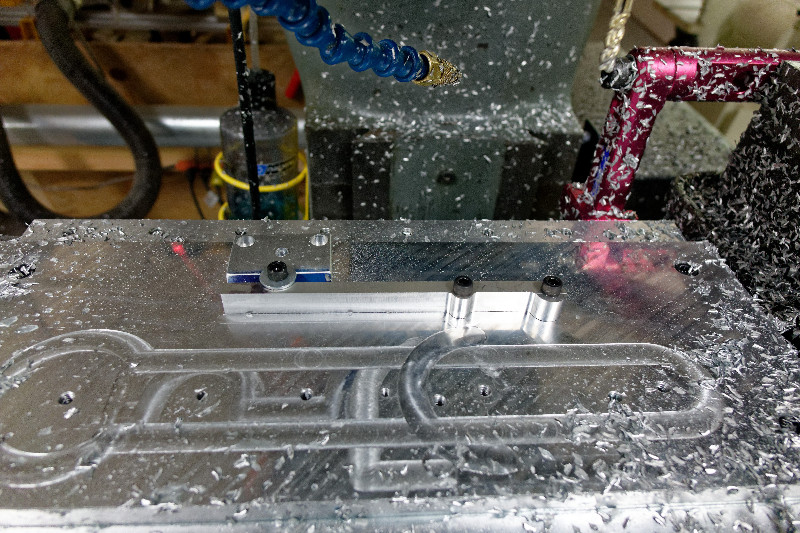

Now that the Bridgeport is in place, machining is a bit easier

The stand is starting to take shape

Somewhat complete. Waiting on Chinese electromagnets

On the glassworking bench. The spring applied, electrically releasing joints don't work yet, so it's being tested with friction joints. Yeah, I know that aluminum against aluminum joints suck and rapidly gall into uselessness, but I need to see if the basic concept is valid

Clamp arm is too short, so make a longer one

The CNC Bridgeport makes it easy

Matt Gieseler, testing Proto 1

He does his best to make it seem useful. It barely works, and I thank him for his heroic effort to make it look good

Overall, the concept was validated. I was confident that the basic idea was sound. Many weaknesses were observed. Much work remains to be done