After months of use, both in the beta test and with Version 1, many suggestions for improvement were made. The biggest area of improvement is smoothness. Glassworkers want it to move as smoothly as possible

Here's a list of improvements planned for Version 2

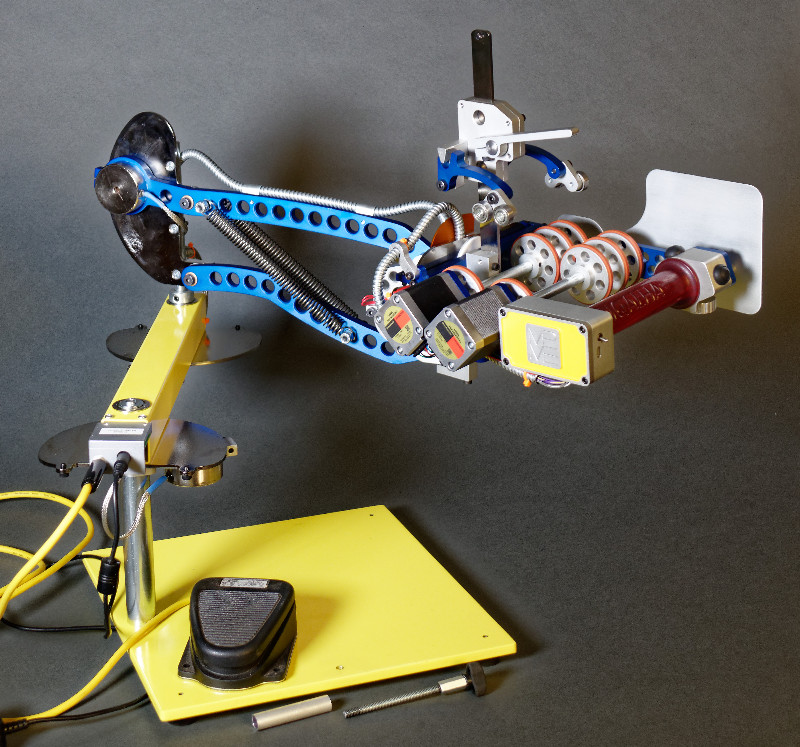

Ball bearings on the horizontal arm to increase smoothness of motion

Ball bearings and new magnet design on twist axis to increase smoothness of motion

Additional control mode that locks twist axis while allowing vertical motion

New software with many improved functions

Hard stops on horizontal motion to prevent over-rotation

Metal mesh covering on magnet wires to protect against heat

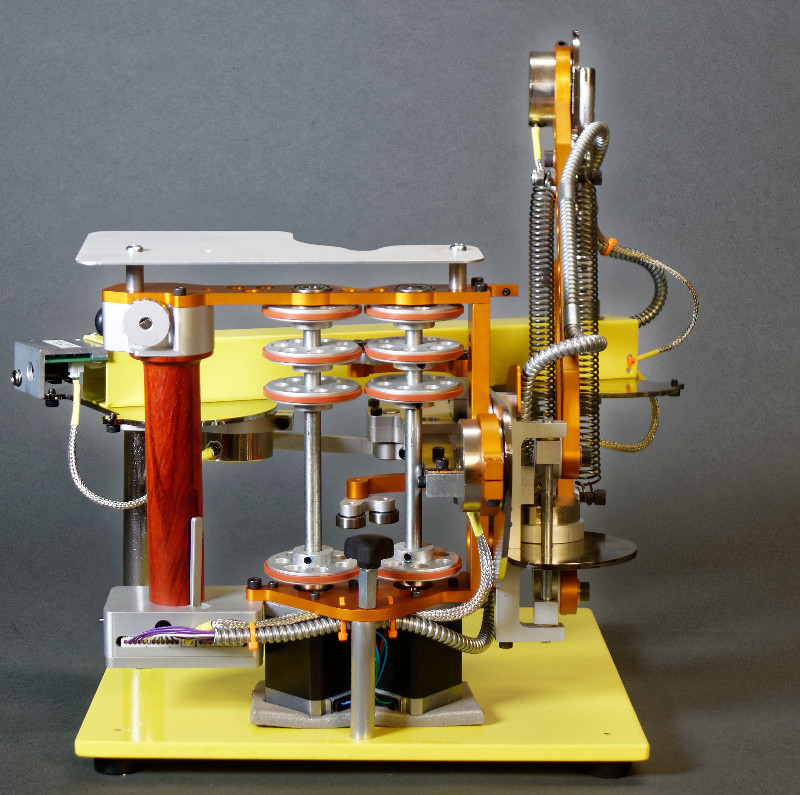

Making new drive rollers

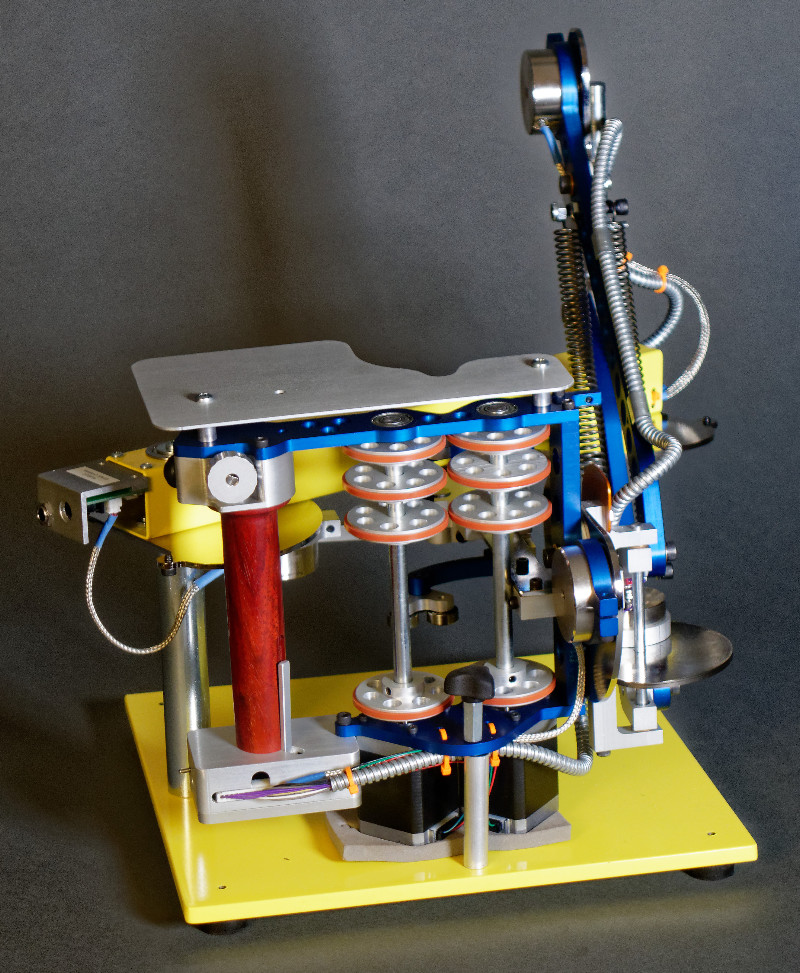

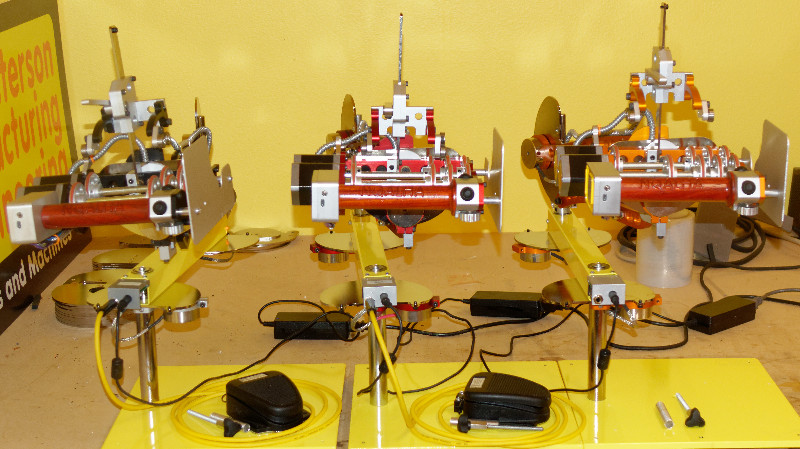

Adding drive rollers, from 6 to 8, gives more flexibility. In this configuration, it's possible to hold short pieces

Laser cut steel parts, ready for plating. Zinc was a poor choice, I'm investigating nickel and nickel-chrome

Powder coated parts are ready

Handles are ready to go. The previous handle design with glued laminations looked cool, but wasn't strong enough

Parts have arrived from the anodizer and plater. They look great!

I will be evaluating nickel-chrome and electoless nickel as replacements for the zinc plating in Version 1

Assembly starts tomorrow

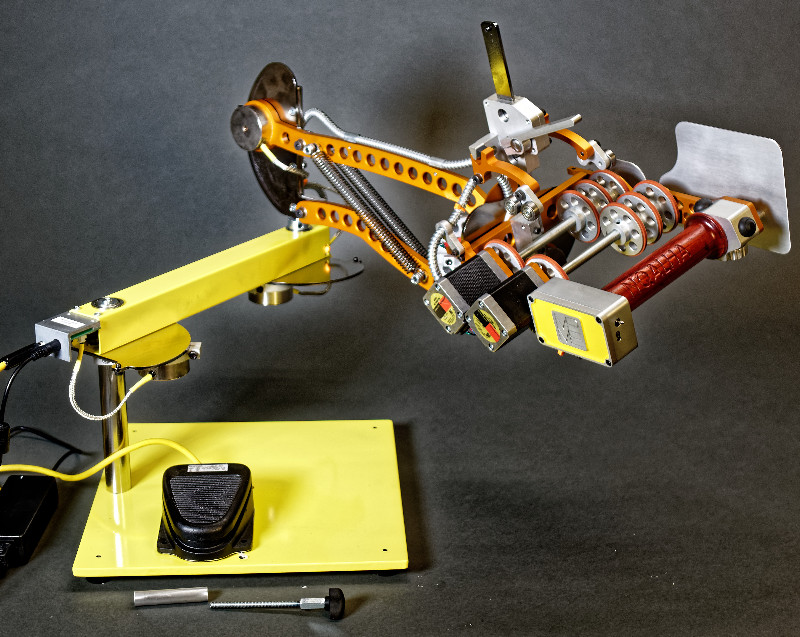

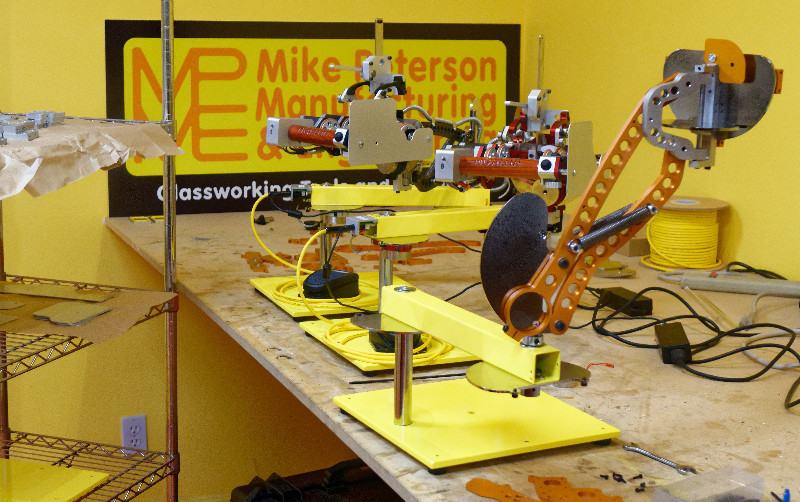

The first production unit is assembled

Next step will be to test the nickel-chrome plating

So far, it looks and works great!

After I'm satisfied that it will do the job, I will send the rest of the production run to the plater

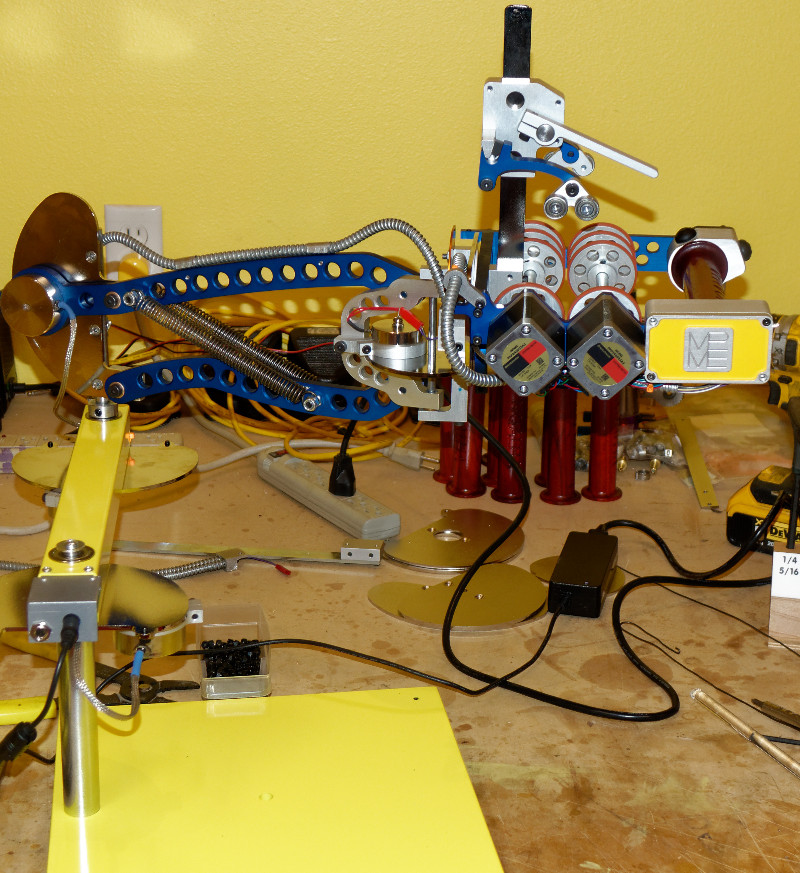

My improvised photo studio

The nickel chrome plating works well, production continues

Here's the first Version 2 unit in shipping position. Note the secure screw lock

Another view

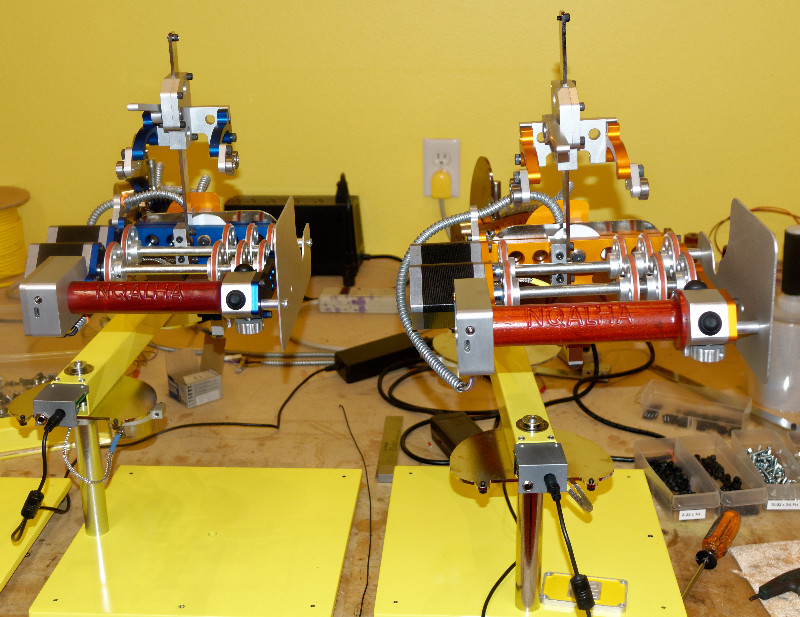

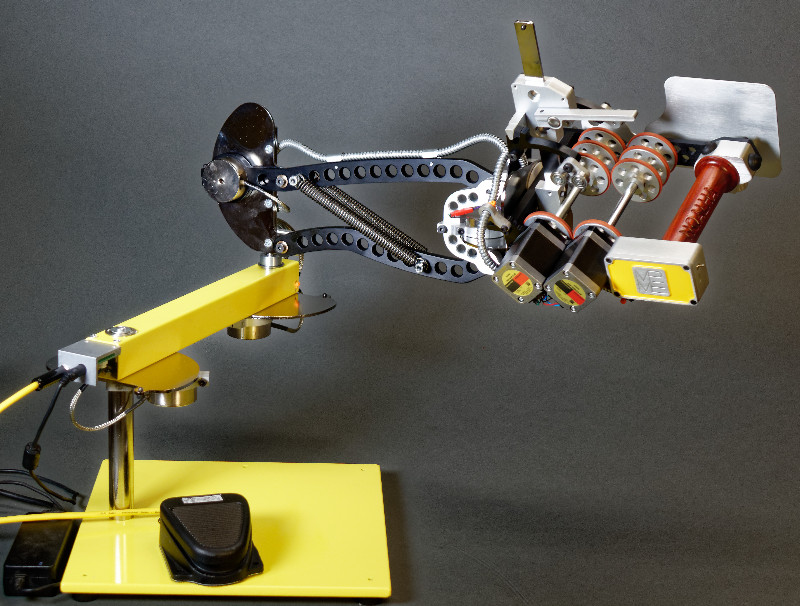

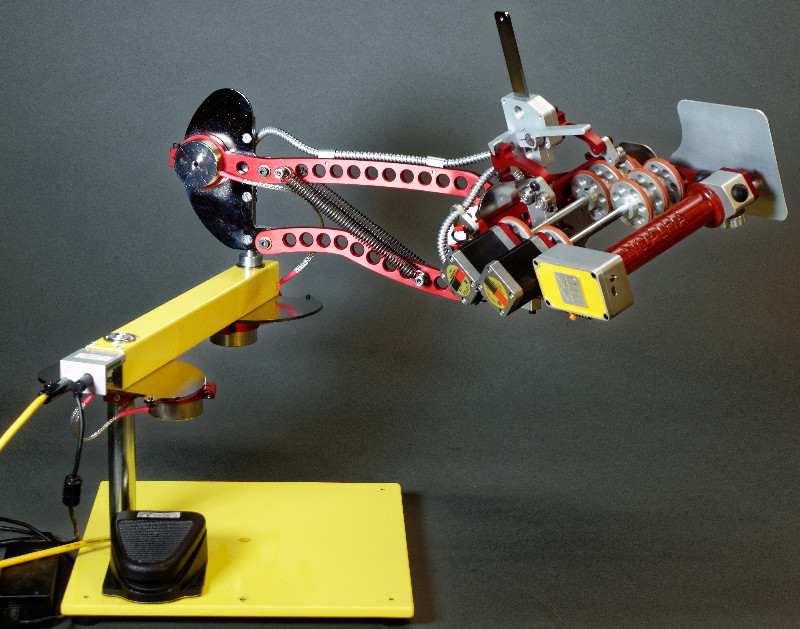

Here's the second one

Another view

Fourth and Fifth in progress

Fourth one

Fifth one

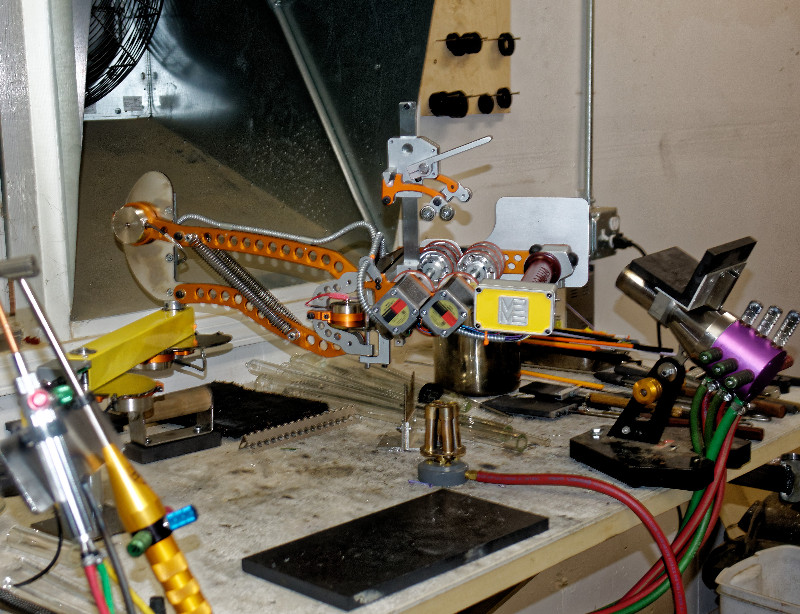

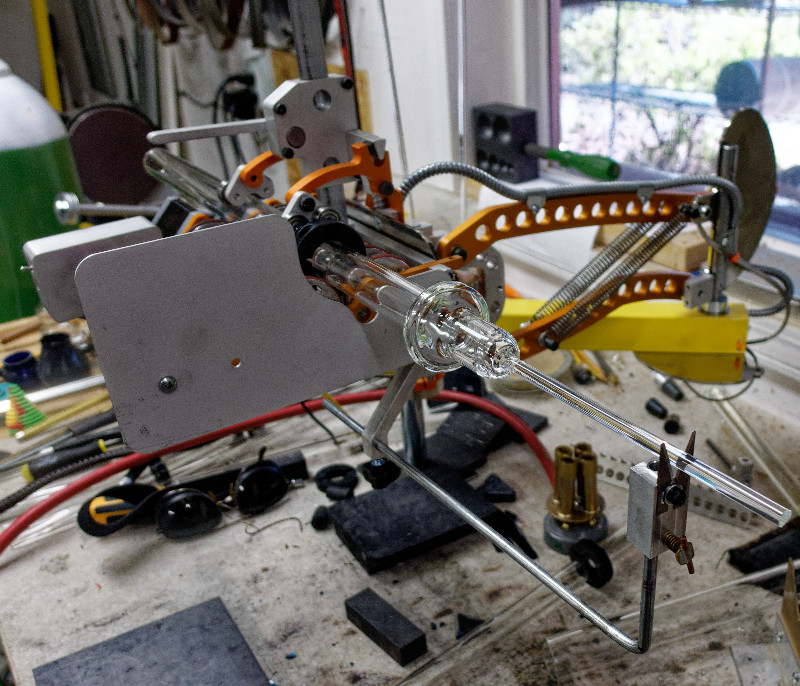

My personal Version 2 NQALHA, on the glass bench

Production continues

Production run 1 complete

Units in stock

Production of lock collars is complete

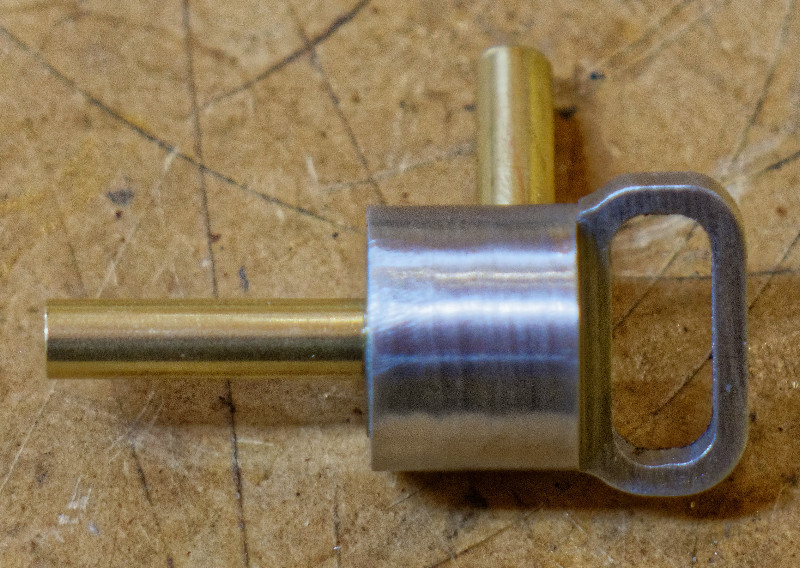

Development continues on the new integrated blowhose swivel

It eliminates the need for lock collars in many situations, and provides a quick-release, ball bearing blowhose connection

Today's version improves sealing while retaining the free motion of the previous prototype

When I made the last run of lock collars, I assumed that 25.4mm would be the biggest size required

Then, a customer asked for larger sizes

38 and 50mm are complete

Experimental right hand punty stabilizer