Version 2.1 solved the twist axis problem, but there was still a small amount of drag on the vertical axis. It was minimal, but my collaborators asked for more smoothness. Version 2.2 uses the hinged magnet design of the V2.1 twist axis on the vertical axis

Here's the prototype

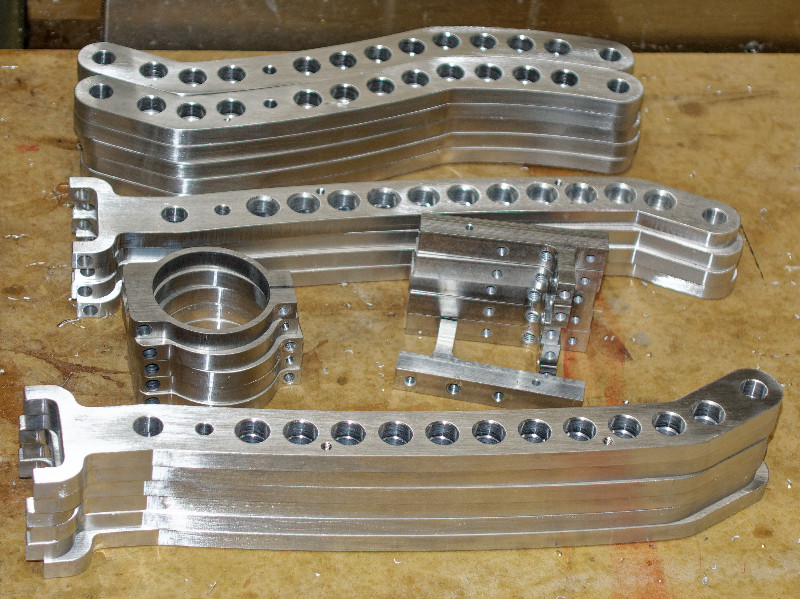

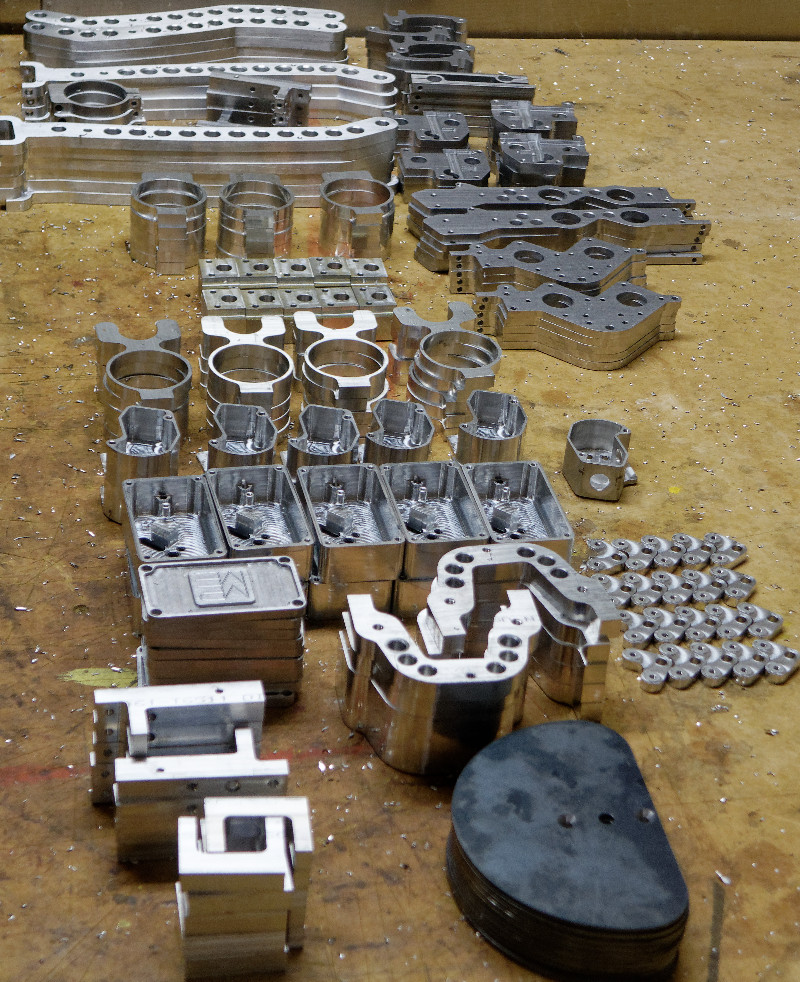

Production underway

Production continues

Production continues

Production continues

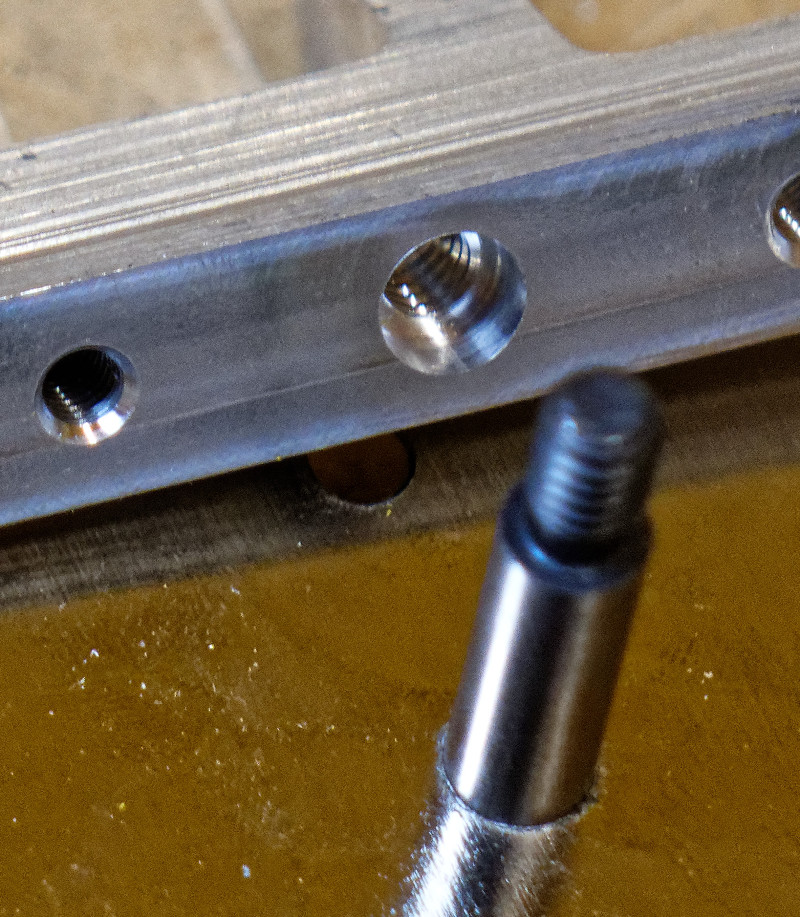

While making parts for NQALHA Version 2.2, I had an idea. The twist axis axle is a critical part of the new design, since the head doesn't depend on the magnet sliding on the plate for support. In Version 2.1, I used a very uncommon, special order, expensive 1 1/8" shoulder screw that seated on the magnet plate. I prefer using common parts, so I redesigned the axle to go through the plate, into a precise counterbore in the underlying structure. This allows use of a common 1 1/2" shoulder screw and results in a much stronger axle

Production continues. Things were going well until the automatic tool changer failed with an error. Back to maintenance mode. Ahh..the life of a machine shop owner

Production continues. The machined aluminum parts are almost finished. The laser cut steel parts arrived from the metal supplier. I just need to drill and countersink the holes. Magnets are ordered from China. Motors are on their way from Japan. I need to check inventory and order electronic parts. Each NQALHA has 71 custom made metal parts, and 283 purchased parts. Each one needs to be inventoried, and re-ordered when stock is low. I'm an engineer and craftsman. I never wanted to be a purchasing agent or warehouse manager, but in a one man shop, I must do it all...and do it right

The motors arrived from Japan, at a higher price The Chinese magnets are more expensive. Version 2.2 has more parts, some much more difficult to make. I decided to keep the price the same. I want to make it affordable to glassworkers

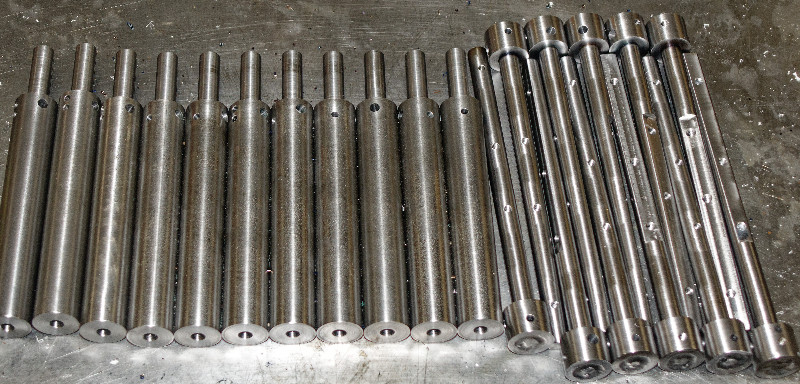

Production continues. I still struggle with the RapidTurn. It works, slowly, and with lots of limitations. I need a real CNC lathe

Production continues

Production of metal parts that will be anodized and plated is complete!

Color anodized parts

Rack of parts ready for assembly

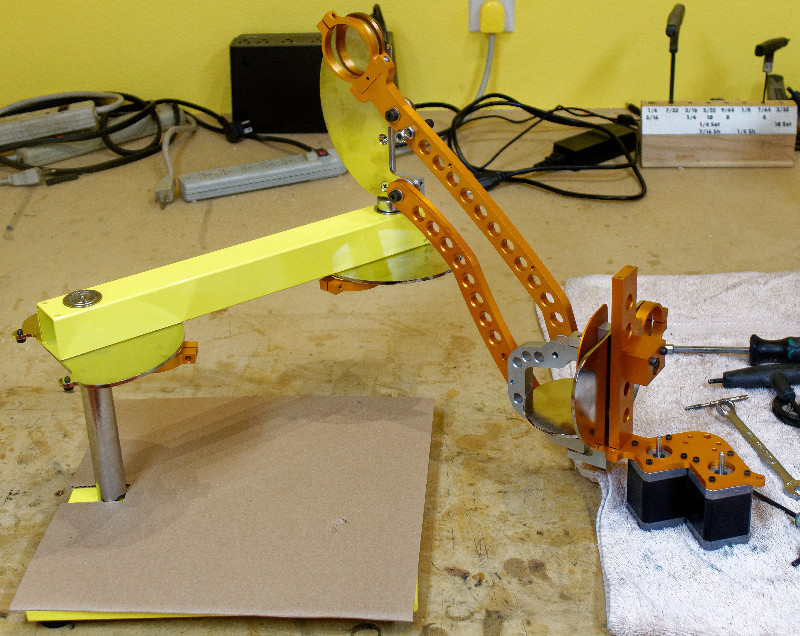

Assembling the first one. Parts fit well and look great

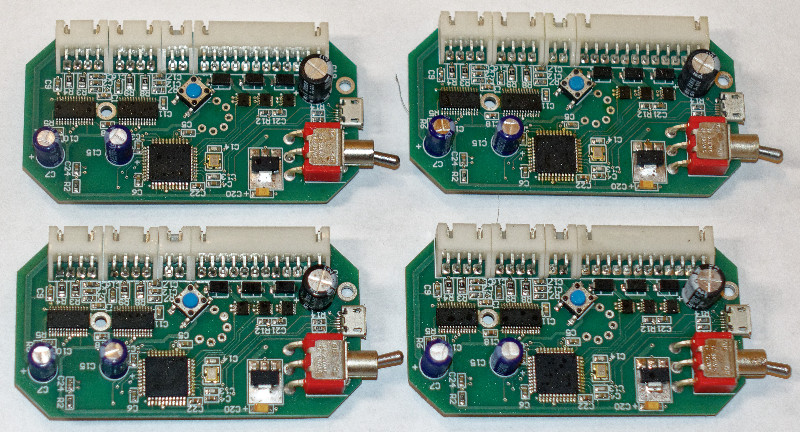

Control boards, with fine pitch surface mount components, assembled by hand under the microscope

The NQALHA has 50 crimp connections onto fine wires. This is the smallest contact, the others aren't much bigger

The first complete Version 2.2 unit

I'm continuing work on the integrated blowhose swivel. It combines a ball bearing blowhose connector with a quick-disconnect method of controlling drift on the NQALHA, eliminating the need for lock collars or other drift control measures. I needed some thumbscrews to fasten the sliding assembly to the rod. A steel screw would ding up the rod. I wanted a nice brass thumbscrew. After searching around for a while and not finding anything I liked, I made some from brass screws and aluminum knobs

Another NQALHA Version 1 is in the shop for an upgrade All Version 1 owners get a free upgrade, paying only shipping

Freshly finished NQALHA handles and controller insulators. I use catalyzed conversion varnish for durability

Here's the first prototype of the NQALHA controller insulator. The controller runs hot, but safe. The aluminum box acts as a heatsink for the motor drivers. Also, stepper motors run hot, but safe, by their nature. Magnets also generate heat and the machine is used in a hot environment. Combine that with an aluminum frame and everything gets hot. This appears to be a very simple and effective solution

I considered giving the insulator addition a version bump, and moving to 2.3. Since the first V2.2 hasn't shipped yet, I will "slipstream" the insulator into Version 2.2